Сантехника жүйелері судың біркелкі ағып кетуін қамтамасыз ету үшін дәл компоненттерге сүйенеді және PPR 90 градус шынтақтары ең маңыздыларының бірі болып табылады. Бұл фитингтер құбырларды тік бұрышпен біріктіріп, тиімділікті төмендетпей күрт бұрылыстар жасайды. Олардың берік конструкциясы тіпті жоғары қысымды жүйелерде де төзімділікті қамтамасыз етеді.

90 градус бұрышы турбуленттілікті азайтады, бұл судың құбырлар арқылы оңай өтуіне мүмкіндік береді. Бұл тозуды азайтады, бұл оларды ұзақ мерзімді пайдалану үшін тамаша етеді.

Тұрғын үй немесе өндірістік сантехника болсын, PPR Elbow 90 DEG сенімді жүйені сақтауда шешуші рөл атқарады.

Негізгі қорытындылар

- PPR 90 градус шынтақ құбырларды 90 градус бұрышпен біріктіреді. Олар судың біркелкі ағуына және сантехникалық жүйелердегі зақымдануды азайтуға көмектеседі.

- Құбырдың өлшемі мен материалын сәйкестендіру арқылы оң жақ шынтақты таңдаңыз. Бұл ағып кетуді тоқтатады және жүйенің жақсы жұмыс істеуін қамтамасыз етеді. Орнатпас бұрын әрқашан олардың сәйкес келетінін тексеріңіз.

- PPR шынтақтарын ұзаққа созу үшін жиі тексеріп, тазалаңыз. Бұл жүйенің жақсы жұмыс істеуін қамтамасыз етеді және қымбат жөндеулерді болдырмайды.

PPR шынтақ 90 DEG түсіну

Анықтамасы және мақсаты

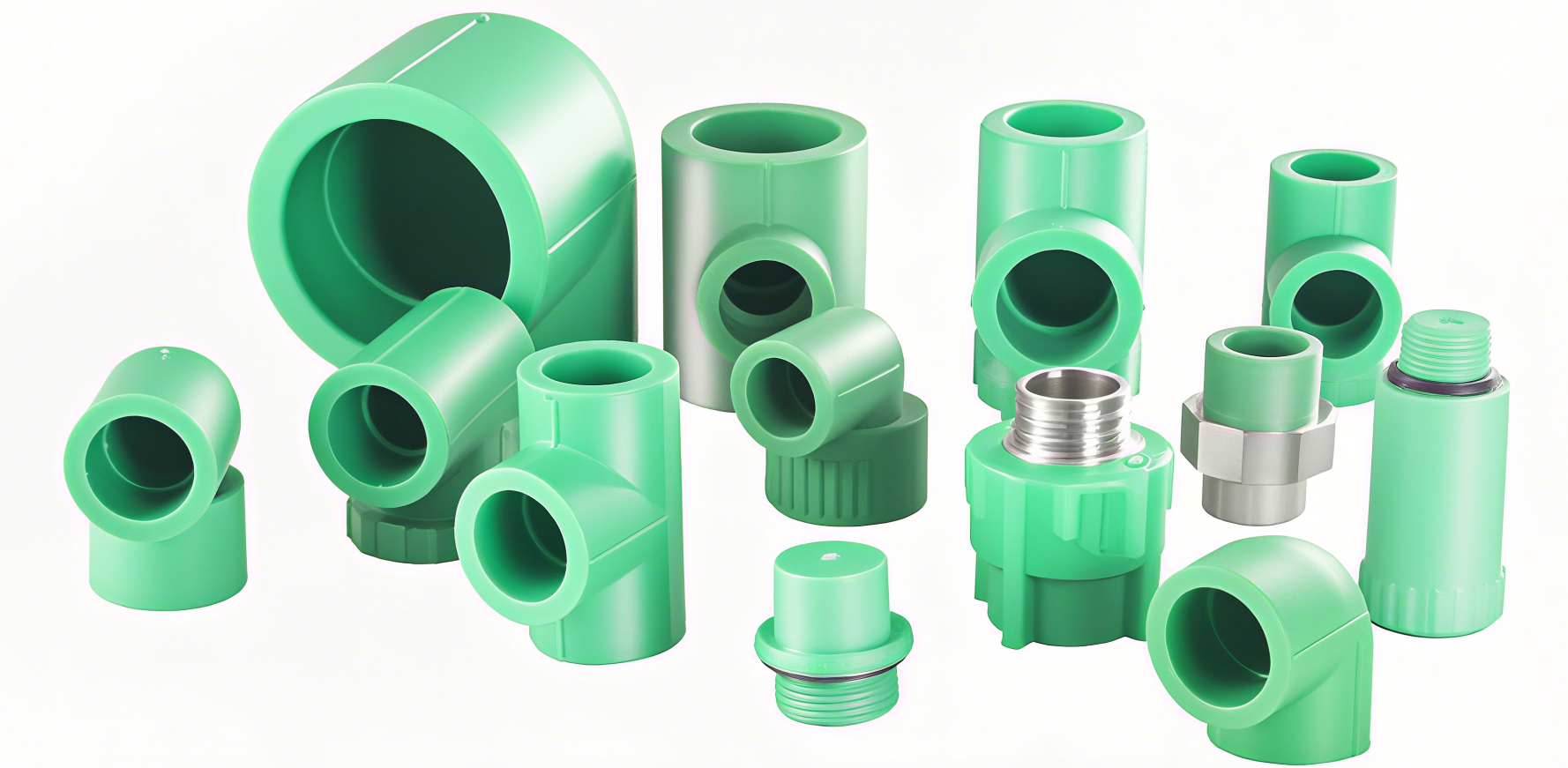

A PPR шынтақ 90 DEGекі құбырды тік бұрышпен қосуға арналған арнайы құбыр арматурасы болып табылады. Оның негізгі мақсаты - су ағынын бұзбай, сантехникалық жүйелердегі біркелкі бағытты өзгертуге мүмкіндік беру. Бұл шынтақтар төзімділігімен және тозуға төзімділігімен танымал полипропилен кездейсоқ сополимерінен (PPR) жасалған.

Сантехникада өткір бұрылыстар жиі турбуленттілік пен қысымның жоғалуына әкелуі мүмкін. PPR Elbow 90 DEG тұрақты ағынды сақтай отырып, бұл мәселелерді азайтады. Бұл оны тұрғын үй және өнеркәсіптік сантехникалық жүйелерде маңызды құрамдас етеді. Сумен жабдықтау, жылыту жүйелері немесе химиялық тасымалдау үшін болсын, бұл шынтақтар тиімділік пен сенімділікті қамтамасыз етеді.

Негізгі мүмкіндіктер мен артықшылықтар

PPR Elbow 90 DEG фитингтері заманауи сантехникалық тәжірибеде ерекшеленетін бірқатар мүмкіндіктермен келеді:

- Төзімділік: Бұл шынтақтар соққыға және тозуға төзімді, коррозиясыз ұзақ мерзімді өнімділікті қамтамасыз етеді.

- Шығындық тиімділік: Бастапқыда олар ПВХ фитингтеріне қарағанда қымбатырақ болғанымен, олардың ұзақ қызмет ету мерзімі уақыт өте келе техникалық қызмет көрсету шығындарын азайтады.

- Қоршаған ортаның пайдасы: PPR қайта өңдеуге жарамды, сондықтан оны экологиялық тұрғыдан ойлайтын құрылысшылар үшін тұрақты таңдау жасайды.

- Төмен жылу өткізгіштік: Бұл мүмкіндік жылу жоғалуын азайтады, бұл шынтақтарды ыстық су жүйелері үшін өте қолайлы етеді.

- Тегіс ағын сипаттамалары: Ішкі бет үйкелісті азайтып, жақсырақ су ағынын қамтамасыз етеді және жүйенің жалпы тиімділігін арттырады.

Бұл артықшылықтар PPR Elbow 90 DEG фитингтерінің сантехникалық жүйелерде неге танымал болғанын түсіндіреді. Олар тұрғын үйлерді сумен жабдықтауды, өнеркәсіптік сұйықтықтарды тасымалдауды және тіпті ауылшаруашылық суаруларын өңдеуге жеткілікті әмбебап.

Шынтақтарды азайтуға қарсы стандартты

PPR Elbow 90 DEG фитингтері екі негізгі түрде келеді: стандартты және кішірек шынтақ. Олардың арасындағы айырмашылықты түсіну нақты қолданбалар үшін дұрысын таңдауға көмектеседі.

- Стандартты шынтақтар: Олардың екі ұшында бірдей диаметрі бар, бұл оларды бірдей өлшемдегі құбырларды қосуға қолайлы етеді. Олар әдетте қарапайым сантехникалық қондырғыларда қолданылады.

- Шынтақтарды азайту: Бұлардың әр ұшында әртүрлі диаметрлер бар, бұл оларға әртүрлі өлшемдегі құбырларды қосуға мүмкіндік береді. Олар құбыр өлшемдері өзгеретін жүйелер үшін өте қолайлы, мысалы, магистральдық су құбырынан кішірек тармақтық желілерге ауысу.

Екі түрі де бірдей беріктік пен тиімділікті ұсынады. Олардың арасында таңдау сантехникалық жүйенің нақты талаптарына байланысты.

PPR Elbow 90 DEG фитингтеріне өсіп келе жатқан сұраныс олардың заманауи сантехниканың қажеттіліктерін қанағаттандыру қабілетін көрсетеді. Нарықтық зерттеулер көрсеткендей, бұл арматура олардың коррозияға төзімділігі мен ұзақ мерзімділігі үшін қолайлы, көбінесе 50 жылдан астам қызмет етеді. Құрылысшылар да олардың экологиялық таза табиғатын жоғары бағалайды, өйткені олар зиянды заттарды ерітпейді және судың сапасын сақтауға көмектеседі.

Дұрыс PPR шынтағын таңдау 90 DEG

Құбыр жүйелерімен үйлесімділік

Дұрыс PPR Elbow 90 DEG таңдау оның құбыр жүйесіне сәйкес келуін қамтамасыз етуден басталады. Құбырлар әртүрлі материалдарда, өлшемдерде және қосылым түрлерінде келеді, сондықтан шынтақ мінсіз туралануы керек. Мысалы, PPR құбырларымен жұмыс істеп жатсаңыз, үйлесімділікті сақтау үшін шынтақ PPR-дан жасалған болуы керек. Бұл сенімді бекітуді қамтамасыз етеді және ағып кетуді болдырмайды.

Құбырдың диаметрі тағы бір маңызды фактор болып табылады. Құбыр өлшеміне сәйкес келмейтін шынтақты пайдалану тиімсіздікке немесе тіпті жүйенің істен шығуына әкелуі мүмкін. Сатып алу алдында әрқашан өлшемдерді екі рет тексеріңіз. Бұған қоса, қосылым түрін қарастырыңыз - ол бұрандалы, дәнекерленген немесе итерілген. Әрбір түрі біркелкі жұмыс істеу үшін нақты шынтақ дизайнын қажет етеді.

Кеңес: Күмәндансаңыз, сәйкессіздіктерді болдырмау үшін өндірушінің нұсқауларымен кеңесіңіз немесе сантехника маманынан кеңес сұраңыз.

Қысым және температура көрсеткіштері

Барлық PPR Elbow 90 DEG фитингтері бірдей жасалмаған. Кейбіреулер басқаларға қарағанда жоғары қысым мен температураны өңдеуге арналған. Біреуін таңдамас бұрын, сантехникалық жүйеңіздің талаптарын бағалаңыз. Мысалы, ыстық су жүйелері жоғары температураға төзімді шынтақтарды қажет етеді, ал өнеркәсіптік қондырғылар төтенше қысымға төтеп бере алатын фитингтерді қажет етуі мүмкін.

Көптеген PPR шынтақтары анық белгіленген қысым мен температура көрсеткіштерімен келеді. Бұл рейтингтер фитингтің өнімділікке нұқсан келтірмей өңдей алатын максималды шектеулерін көрсетеді. Бұл сипаттамаларды елемеу мерзімінен бұрын тозуға немесе тіпті жүйенің істен шығуына әкелуі мүмкін.

Ескерту: PPR материалы өзінің тамаша термиялық және қысымға төзімділігімен танымал, бұл оны тұрғын үй және өнеркәсіптік қолданбалар үшін сенімді таңдау етеді.

Қарастырылатын сапа стандарттары

Сантехникаға келетін болсақ, сапасы келіспейді. Жоғары сапалы PPR Elbow 90 DEG фитингтері ұзақ қызмет етіп қана қоймайды, сонымен қатар жүйеңіздің қауіпсіздігі мен тиімділігін қамтамасыз етеді. ISO және ASTM сияқты халықаралық стандарттарға сәйкес келетін өнімдерді іздеңіз. Бұл сертификаттар фитингтердің қатаң сынақтан өткеніне және ең жоғары салалық стандарттарға сәйкес келетініне кепілдік береді.

Міне, сапаны қамтамасыз етудің кейбір негізгі көрсеткіштері:

- ISO және ұлттық стандарттарға сәйкес келетін өнімдер.

- Сұраныс бойынша жиі қол жетімді болатын CE және ASTM сертификаттары.

- Дұрыс пайдалану кезінде 50 жылға дейін кепілдік берілген қызмет мерзімі.

Сертификатталған өнімдерді таңдау сіздің сантехникалық жүйеңіз ұзақ уақытқа созылатынын біле отырып, жан тыныштығын береді. Бұл сонымен қатар қымбат жөндеу немесе ауыстыру қаупін азайтады.

Pro Кеңес: Әрқашан сапаға басымдық беретін және салалық стандарттарды сақтайтын беделді жеткізушілерден сатып алыңыз.

PPR шынтақ 90 DEG орнату

Дұрыс орнату аPPR шынтақ 90 DEGқауіпсіз және ағып кетпейтін қосылымды қамтамасыз етеді. Дұрыс қадамдарды орындау және дұрыс құралдарды пайдалану процесті қарапайым және тиімді ете алады. Міне, оны дұрыс алу үшін білуіңіз керек нәрсенің бәрі.

Қадамдық орнату нұсқаулығы

PPR Elbow 90 DEG орнату бірнеше қарапайым қадамдарды қамтиды:

- Құралдарыңызды дайындаңыз: Құбыр кескішті, PPR дәнекерлеу машинасын және өлшеуіш таспаны жинаңыз. Барлық құралдардың таза және жақсы жұмыс күйінде екеніне көз жеткізіңіз.

- Өлшеу және кесу: Қажетті құбыр ұзындығын анықтау үшін өлшеуіш таспаны пайдаланыңыз. Түтіктерді мұқият кесіп тастаңыз, тегіс жиектері тығыз орналасуын қамтамасыз етеді.

- Фитинг пен құбырды қыздырыңыз: PPR дәнекерлеу машинасын қосып, шынтақ пен құбыр ұштарын қыздырыңыз. Беттері аздап жұмсарғанша күтіңіз.

- Бөлшектерді қосыңыз: Материал әлі жылы болған кезде құбыр ұштарын шынтақ ішіне итеріңіз. Күшті байланыс жасау үшін оларды бірнеше секунд бойы тұрақты ұстаңыз.

- Басылыңыз: Байланыстың табиғи түрде суытылуына мүмкіндік беріңіз. Осы уақыт ішінде тураланбау үшін құбырларды жылжытпаңыз.

Осы қадамдарды орындау арқылы сіз берік және сенімді қосылымға қол жеткізе аласыз.

Қажетті құралдар мен жабдықтар

PPR Elbow 90 DEG орнату үшін сізге мыналар қажет:

- Құбыр кескіш

- PPR дәнекерлеу машинасы

- Өлшеу лентасы

- Маркер (міндетті емес, өлшемдерді белгілеу үшін)

Бұл құралдардың дайын болуы орнату процесінің бірқалыпты болуын қамтамасыз етеді.

Болдырмауға болатын жалпы қателер

Тіпті кішкентай қателер ағып кетуге немесе әлсіз байланыстарға әкелуі мүмкін. Міне, кейбір жиі кездесетін қателіктерге назар аудару керек:

- Өлшемдерді өткізіп жіберу: Дәл өлшемеу құбырлардың тураланбауына әкелуі мүмкін.

- Біркелкі емес кесу: Кесілген немесе бұрышты кесу дұрыс орнатуға кедергі келтіруі мүмкін.

- Қызып кету немесе қызып кету: Құбырды және шынтақты тым ұзақ немесе тым қысқа қыздыру байланыстыруды әлсіретуі мүмкін.

- Салқындату кезінде қозғалу: Қосылым салқындағанша құбырларды ауыстыру дұрыс емес туралауды тудыруы мүмкін.

Бұл қателерді болдырмау қауіпсіз және ұзақ орнатуды қамтамасыз етуге көмектеседі.

PPR шынтақ 90 DEG ұстау

Тұрақты тексеру және тазалау

сақтау аPPR шынтақ 90 DEGең жақсы жағдайда тұрақты тексеруден басталады. Кез келген көрінетін жарықтар, ағып кету немесе түссіздену бар-жоғын тексеру ақауларды ерте анықтауға көмектеседі. Ықтимал мәселелерді анықтау үшін бірнеше ай сайын жылдам визуалды сканерлеу жеткілікті.

Тазалау да соншалықты маңызды. Уақыт өте келе фитингтің ішінде минералды шөгінділер немесе қоқыс жиналып, су ағынына әсер етуі мүмкін. Жүйені таза сумен шаю бұл бітелуді жояды. Қатты шөгінділер үшін сантехникалық жүйелерге арналған жұмсақ тазалау ерітіндісі жақсы жұмыс істейді. Қалдықтарды қалдырмау үшін әрқашан мұқият шайыңыз.

Кеңес: Уақыт пен күш-жігерді үнемдеу үшін сантехникаға күнделікті техникалық қызмет көрсету кезінде тексерулер мен тазалауды жоспарлаңыз.

Тозуды анықтау

Тіпті PPR Elbow 90 DEG сияқты берік арматура уақыт өте келе тозу белгілерін көрсете алады. Су қысымының төмендеуі, әдеттен тыс шулар немесе көрінетін зақым сияқты белгілерді іздеңіз. Бұл ішкі бітелуді немесе құрылымның әлсіреуін көрсетуі мүмкін.

Осы белгілердің кез келгенін байқасаңыз, тез әрекет етіңіз. Тозуды елемеу ағып кету немесе жүйенің істен шығуы сияқты үлкенірек мәселелерге әкелуі мүмкін. Тозған фитингтерді дереу ауыстыру сантехникалық жүйенің сенімділігін қамтамасыз етеді.

Ұзақ өмір сүрудің алдын алу шаралары

Профилактикалық қызмет көрсету PPR Elbow 90 DEG фитингтерінің қызмет ету мерзімін ұзартады. Тұрақты тексерулер, тазалаудың минималды талаптары және үнемді жөндеу бұл арматураларға техникалық қызмет көрсетуді жеңілдетеді. Төмендегі кестеде негізгі техникалық қызмет көрсету тәжірибелері мен олардың артықшылықтары көрсетілген:

| Дәлелдер түрі | Сипаттама |

|---|---|

| Тұрақты тексерулер | Тұрақты тексерулер мен техникалық қызмет көрсету ықтимал мәселелерді анықтау үшін өте маңызды, осылайша сенімділікті қамтамасыз етеді. |

| Техникалық қызмет көрсетуге сұраныс | Техникалық қызмет көрсету аз талап етеді, өйткені PPR фитингтері ағып кетуге және зақымдануға қарсы тұрады, бұл жиі жөндеу қажеттілігін азайтады. |

| Шығындық тиімділік | PPR фитингтері қолжетімді және ұзағырақ қызмет етеді, бұл ауыстыру шығындарын азайтады. |

Осы шараларды орындау арқылы үй иелері мен кәсіпқойлар өздерінің сантехникалық жүйелерінің өнімділігі мен ұзақ мерзімділігін барынша арттыра алады.

Pro Кеңес: Әрқашан жоғары сапалы фитингтерді пайдаланыңыз және орнату және техникалық қызмет көрсету бойынша өндірушінің нұсқауларын орындаңыз. Бұл оңтайлы өнімділікті қамтамасыз етеді және ұзақ мерзімді шығындарды азайтады.

PPR Elbow 90 DEG артықшылықтары мен қолданулары

Тұрғын үйдегі сантехникадағы артықшылықтар

PPR Elbow 90 DEG фитингтеріүй иелеріне олардың сантехникалық қажеттіліктері үшін сенімді шешім ұсыныңыз. Бұл шынтақтар жоғары температура мен қысымға қарсы тұру қабілетінің арқасында ыстық және суық су жүйелеріне өте ыңғайлы. Олардың тегіс ішкі беті үйкелісті азайтып, бүкіл үйде тұрақты су ағынын қамтамасыз етеді.

Бір ерекше ерекшелігі - олардың энергия тиімділігі. PPR шынтақтары мысға қарағанда жақсы оқшаулайды, бұл ыстық су жүйелеріндегі жылу жоғалуын азайтады. Бұл үй иелеріне судың тұрақты температурасын сақтай отырып, қуат төлемдерін үнемдеуге көмектеседі. Сонымен қатар, бұл фитингтер үнемді. Тот баспайтын болаттан жасалған баламалармен салыстырғанда оларды орнату арзанырақ, бұл оларды тұрғын үй жобалары үшін бюджеттік таңдау жасайды.

| Пайда түрі | Сипаттама |

|---|---|

| Энергия тиімділігі | Мысқа қарағанда жақсы оқшаулайды, жылу жоғалтуды азайтады |

| Шығындарды үнемдеу | Тот баспайтын болаттан гөрі төменірек материал мен орнату құны |

Осы артықшылықтармен PPR Elbow 90 DEG фитингтері заманауи үйлер үшін танымал таңдау болды. Олар ұзақ мерзімділікті, тиімділікті және қол жетімділікті біріктіреді, бұл оларды тұрғын үй су құбырлары жүйелері үшін өте қолайлы етеді.

Коммерциялық және өнеркәсіптік жүйелердегі қолданбалар

Коммерциялық және өнеркәсіптік жағдайларда PPR Elbow 90 DEG фитингтері әмбебаптығы мен беріктігі арқасында жарқырайды. Бұл шынтақтар жоғары қысымды жүйелермен оңай жұмыс істейді, бұл оларды зауыттарға, кеңсе ғимараттарына және ірі су тарату желілеріне қолайлы етеді.

Олардың химиялық заттарға және коррозияға төзімділігі оларды өнеркәсіптік сұйықтықтарды тасымалдау үшін өте қолайлы етеді. Салқындату жүйелеріне, химиялық өңдеуге немесе жылыту қолданбаларына арналған болса да, PPR шынтақтары сенімді өнімділікті қамтамасыз етеді. Олар сонымен қатар ауылшаруашылық жұмыстарына тиімді су ағынын сақтауға көмектесетін ірі суару жүйелеріне қолдау көрсетеді.

Кәсіпорындар ұзақ қызмет ету мерзімінен пайда көреді, бұл техникалық қызмет көрсету шығындары мен тоқтап қалу уақытын азайтады. PPR Elbow 90 DEG фитингтерімен коммерциялық және өнеркәсіптік жүйелер ондаған жылдар бойы бірқалыпты жұмыс істей алады.

Қоршаған орта және шығындардың тиімділігі

PPR Elbow 90 DEG фитингтері сантехникалық жүйелер үшін экологиялық таза таңдау болып табылады. Қайта өңдеуге болатын материалдардан жасалған олар тұрақты құрылыс тәжірибесіне ықпал етеді. Металл арматурадан айырмашылығы, олар суға зиянды заттарды жібермейді, бұл қауіпсіз және таза сумен қамтамасыз етеді.

Олардың құнының тиімділігі тағы бір маңызды артықшылық болып табылады. Бастапқы инвестиция ПВХ фитингтерінен сәл жоғары болуы мүмкін болса да, олардың беріктігі мен техникалық қызмет көрсетудің төмен талаптары ұзақ мерзімді перспективада ақшаны үнемдейді. Құрылысшылар да, үй иелері де бюджетті бұзбай, жоғары өнімділікті қамтамасыз ету қабілетін бағалайды.

PPR Elbow 90 DEG фитингтерін таңдау арқылы пайдаланушылар тиімділік пен сенімділіктің заманауи стандарттарына сәйкес келетін жасыл, үнемді сантехникалық шешімді пайдалана алады.

PPR Elbow 90 DEG фитингтері заманауи сантехникалық жүйелерде таптырмас екенін дәлелдеді. Олардың су ағынын жақсарту, тозуға қарсы тұру және ұзақ мерзімді беріктігін қолдау қабілеті оларды тұрғын үй, коммерциялық және өнеркәсіптік қолданбалар үшін таңдаулы етеді. Бұл арматура, әсіресе, сенімді құбыр қосылымдары қажет болатын қалалық инфрақұрылым өсіп келе жатқан аудандарда өте құнды.

Чжэцзян провинциясының Нинбо қаласында орналасқан біздің компания жоғары сапалы пластикалық құбырларға, фитингтерге және клапандарға маманданған. Экспорттаудағы көп жылдық тәжірибемізбен біз UPVC, CPVC, PPR және HDPE құбырларын, сондай-ақ спринклер жүйелері мен су есептегіштерін қоса алғанда, өнімдердің кең ауқымын ұсынамыз. Барлық өнімдер озық техника мен премиум материалдар арқылы жасалған, бұл ерекше өнімділікті қамтамасыз етеді.

Біз командамызда ұжымдық атмосфераны нығайтуға сенеміз. Тәртіп пен ұқыптылықты теңестіре отырып, біз ұйымшылдықты нығайтып, жұмыс сапасын жақсартамыз. Бұл философия біздің сенімді және инновациялық шешімдерді жеткізуге ұмтылуымызға ықпал етеді.

Сантехниканың оңтайлы өнімділігі үшін әрқашан сапалы фитингтерге және дұрыс орнатуға басымдық беріңіз.

Бізбен хабарласыңы:

Мақала авторы: Кимми

E-mail: kimmy@pntek.com.cn

Телефон: 0086-13306660211

Жиі қойылатын сұрақтар

1. PPR Elbow 90 DEG фитингтерін басқа материалдардан не жақсырақ етеді?

PPR шынтақтары коррозияға төзімді, жоғары температураны ұстайды және 50 жылдан астам қызмет етеді. Олардың тегіс интерьері судың тиімді ағынын қамтамасыз етеді, бұл оларды ұзақ және экологиялық таза таңдау жасайды.

2. PPR Elbow 90 DEG фитингтерін ыстық су жүйелері үшін пайдалануға бола ма?

Иә!PPR материалы тамаша термиялық төзімділікке ие, бұл шынтақтарды үйлер мен өндірістердегі ыстық су жүйелері үшін тамаша етеді.

Кеңес: Орнатпас бұрын әрқашан температура көрсеткіштерін тексеріңіз.

3. PPR Elbow 90 DEG ауыстыру қажет екенін қалай білемін?

Ағып кетуді, жарықтарды немесе су қысымының төмендеуін іздеңіз. Тұрақты тексерулер бұл мәселелерді ерте анықтауға көмектеседі, бұл сіздің сантехникалық жүйеңіздің сенімділігін қамтамасыз етеді.

Хабарлама уақыты: 19 мамыр 2025 ж